Researchers have optimised a process to turn rubber tyre waste into turbo-stratic graphene, which can be added to concrete to curb carbon emissions, according to a study published in the journal Carbon.

Old Tyres Being Turned into Graphene

Though recycled tyre waste is already a component of Portland cement as a residue of using tyres for fuel, graphene strengthens concrete “at the molecular level,” so less concrete has to be used for roads, according to researchers.

“Concrete is the most-produced material in the world, and simply making it produces as much as 9% of the world’s carbon dioxide emissions,” study co-author James Tour said in a press release.

“If we can use less concrete in our roads, buildings and bridges, we can eliminate some of the emissions at the very start,” said Tour, a chemistry professor at Rice University.

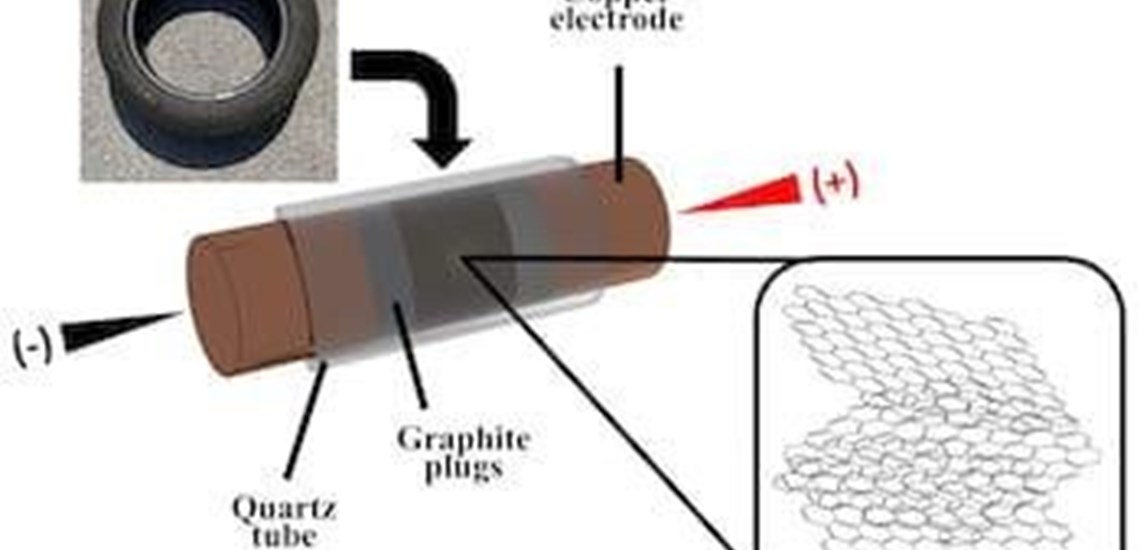

Researchers previously developed a process that involves a jolt of electricity to convert plastic and food waste into graphene, a lab video shows.

The process is called a flash process since it emits a bright flash. Though rubber was more challenging, scientists used Flash Joule Heating to optimise the process, the new study shows. The jolt of electricity removes all but the Carbon atoms from the material.

Those Carbon atoms reassemble into valuable turbo-stratic graphene, which has misaligned layers that are more soluble than graphene produced via exfoliation from graphite. That makes it easier to use in composite materials.

Rubber proved more challenging than food or plastic to turn into graphene, but the lab optimised the process by using commercial pyrolysed waste rubber from tyres. After useful oils are extracted from waste tyres, this carbon residue has until now had near-zero value, Tour said.

Tyre-derived carbon black or a blend of shredded rubber tyres and commercial carbon black can be flashed into graphene. Because turbo-stratic graphene is soluble, it can easily be added to cement to make more environmentally friendly concrete.

The research led by Tour and Rouzbeh Shahsavari of C-Crete Technologies is detailed in the journal Carbon.

The Rice lab flashed tyre-derived carbon black and found about 70% of the material converted to graphene. When flashing shredded rubber tyres mixed with plain carbon black to add conductivity, about 47% converted to graphene. Elements besides carbon were vented out for other uses.

The electrical pulses lasted between 300 milliseconds and 1 second. The lab calculated electricity used in the conversion process would cost about $100 per ton of starting carbon.

The researchers blended minute amounts of tyre-derived graphene—0.1 weight/ per cent (wt%) for tyre carbon black and 0.05 wt% for carbon black and shredded tyres—with Portland cement and used it to produce concrete cylinders. Tested after curing for seven days, the cylinders showed gains of 30% or more in compressive strength. After 28 days, 0.1 wt% of graphene sufficed to give both products a strength gain of at least 30%.

“This increase in strength is in part due to a seeding effect of 2D graphene for better growth of cement hydrate products, and in part due to a reinforcing effect at later stages,” Shahsavari said.