Toyoda Gosei says it is doubling its rubber recycling capacity at the Morimachi Plant in central Japan to accelerate the recycling of rubber used in automobiles

Toyoda Gosei Co., Ltd. Has announced that it is doubling its rubber recycling capacity at its Morimachi Plant in central Japan to accelerate the recycling of rubber used in automobiles.

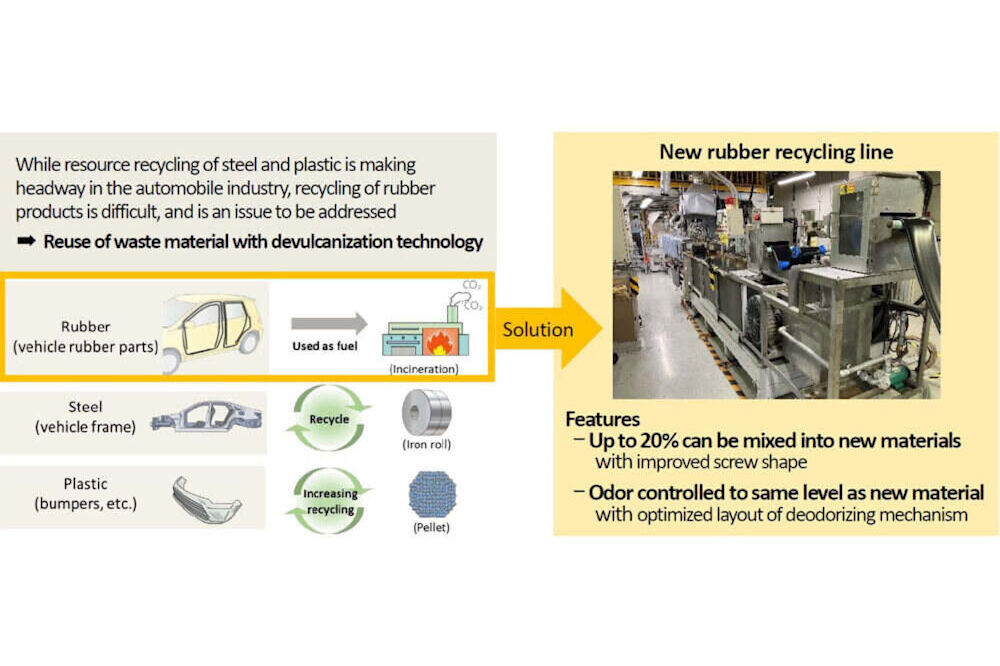

Toyoda Gosei said it began operations of its first recycling line in 2021, using its proprietary devulcanisation technology that can recycle rubber products into high-quality raw materials.

A second line is now being put into operation that will double the previous rubber recycling capacity to 1,200 tons annually. The new line, which is scheduled to start mass production in 2025, incorporates improved technology to raise the quality of the recycled rubber. This enables to increase the percentage of recycled material mixed into new material from several percent up to 20 per cent, which is with this almost all of the waste from opening trim weatherstrips manufactured at the Morimachi Plant can be recycled, Toyoda Gosei said.

Going forward, Toyoda Gosei states it will collaborate with automakers and other bodies to lead the world in rubber recycling.