Sumitomo Rubber Industries will work with Lanzatech to boost the circular economy by focusing on waste recycling

This announcement follows a November 2022 joint development with LanzaTech Global Inc.

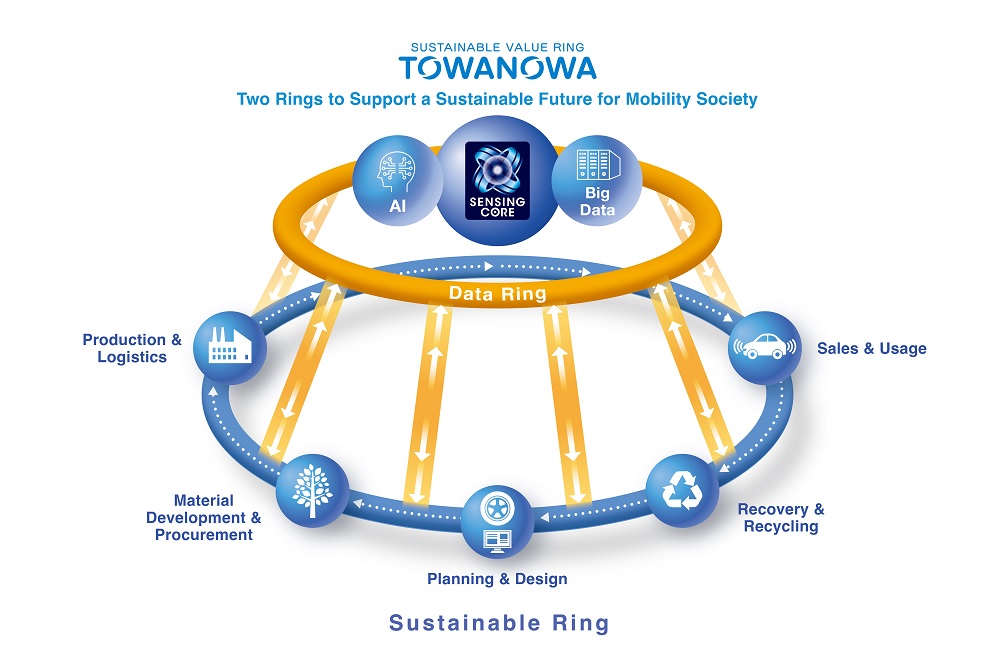

Sumitomo Rubber states that Sumitomo Rubber, along with Sumitomo Electric, will be taking part in this joint development. The three companies will join forces with LanzaTech in joint development, aiming to pioneer groundbreaking technologies that enable a circular economy, transforming waste materials, including rubber, resin, urethane, and metal, into valuable resources. This will accelerate our efforts to create a sustainable society characterised by carbon neutrality and a circular economy-the goals of Sumitomo’s unique circular economy concept, “TOWANOWA.”

Under the circular economy concept “TOWANOWA,” Sumitomo aims aim to recycle and make efficient use of finite resources, all the while capitalising on its reservoir of big data to introduce groundbreaking, value-added solutions to its customers. and comfort.

This time around, says Sumitomo, the company is taking another step forward to accomplish a circular economy for raw materials. The aim is to leverage LanzaTech’s biorecycling technology to turn waste materials like tyres into isoprene, which can be used in new rubber materials.

This will be achieved by gasifying the waste materials and purifying the resulting gas, and then putting them through a fermentation process that transforms the gas into new raw materials. Sumitomo’s end goal, working alongside raw material manufacturers, is to explore the feasibility of establishing a recycling technology that enables the reuse of isoprene as material for rubber and resin.

This follows an agreement with South Korea’s LD Carbon, and the isoprene route follows a path already taken by Bridgestone.

Collaboration is Required

Sumitomo manufactures and sells a diverse selection of tyres globally. It has annual tyre sales totalling 110 million (as of 2022). As new tyres are manufactured and sold, a significant number of tyres are thrown away every year. Many tyres that get discarded in Japan are later incinerated, with the generated heat being put to practical use.

To bring the “TOWANOWA” circular economy concept to life, it is crucial to advance “Recovery and Recycling” initiatives in the tyre business and to create a system that transforms discarded tyres into useful resources. This collaboration is an integral part of Sumitomo’s research and development in recycling technology.

Although individual companies can contribute to building a sustainable society, accomplishing this goal on their own is a daunting task. Success requires fostering collaboration across diverse sectors, involving stakeholders from academia, industry, and government. Moving forward, Sumitomo intends to continue intensifying its endeavours in each process of the circular business concept “TOWANOWA” and use data to boost efficiency in its internal development. Through engaging with diverse external stakeholders, Sumitomo seeks to share cutting-edge information and technology, thereby resolving social issues and creating a sustainable society.