Silicone treatment could offer a low-cost, efficient recovery of SBR rubber materials. The process needs refinement and research into new markets

Canadian University Tackles Rubber Recovery from Car Tyres

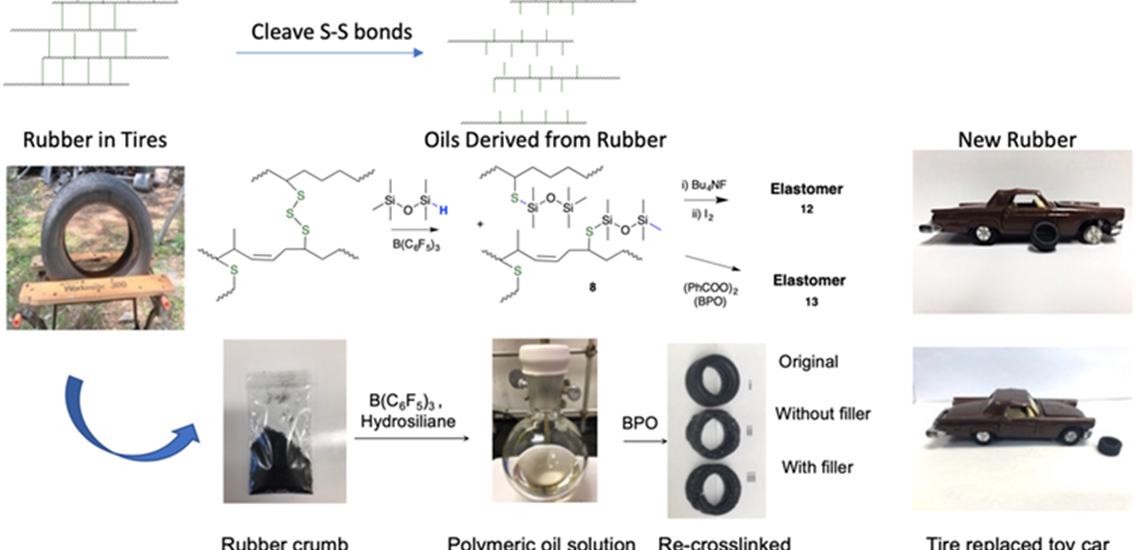

Laboratory testing at Brook Research Group at McMaster University, an efficient and mild process has been developed that uses silicone chemistry to break the sulphur to sulphur bonds that create vulcanised rubber. The silicones selectively cut the sulphur-sulphur connections, leaving only organic chains that can be easily isolated and reused to create new products. This process, originally designed to make new silicones using minimal quantities of a catalyst, has been repurposed to address the sustainability of petroleum-based tyres.

The chemical process requires the supply of powdered rubber. Then, a mild, rapid reaction produced by heating this material with specific silicones at 100C for 45 minutes converts about 90 per cent of the available organic materials into a readily processed pale yellow oil. The remaining substances — such as inorganic carbon, silica, metal and polyester cord fibres — are readily removed by filtration.

The oils recovered from used tyres are very similar in constitution to the virgin polymers initially used to make new tyres. The lab has also demonstrated that they can be repurposed.

In one instance, the recovered polymers were converted back into new rubbers and used to make the tyre of the toy car. The inorganic residue, initially removed by filtration, could also be reused as a reinforcing agent in the new rubber.

There is more work to be done. There needs to be a wider range of products established that can be made from the recovered polymers and reduce the quantity of catalyst required to improve the economics of the process.

The overall process offers an opportunity to close the loop on automobile tyres, as the rubber can be efficiently degraded and then reused to make other useful materials. It provides a new strategy to re-purpose the valuable materials in used tyres and simultaneously address a perplexing environmental problem.

NOTE: Diagram showing the steps in this new process for breaking down rubber tires. Author provided