The FIBER2FIBER project, launched in 2022 in collaboration with the GAIKER technology centre, aimed to develop a new way to take advantage of the textile fraction from tyre recycling through chemical recycling

The management of tyres, which are mainly composed of rubber, steel and textile fibres, requires constantly investigating new ways to recycle them in different applications, since today it is not possible to incorporate all of their components in the manufacturing chain of new tyres. Thus, this project emerged with the aim of achieving the circularity of textile fibres by incorporating them back into the production chain.

Despite this great advance, the recycling of the textile fraction continues to be, today, a pending issue due to its great complexity since it is a mixture of textile fibres of different composition, such as polyesters, polyamides or rayon, and also contaminated to a greater or lesser extent by rubber particles from the process of separating the tyre components through mechanical recycling.

In this context, chemical recycling is presented as a complementary technological solution. Due to the great complexity of the textile fibre fraction of NFVU, it is necessary to approach chemical recycling selectively, that is, focusing only on one type of textile fibre. Therefore, this project focuses on the fraction corresponding to PET-type polyester fibres.

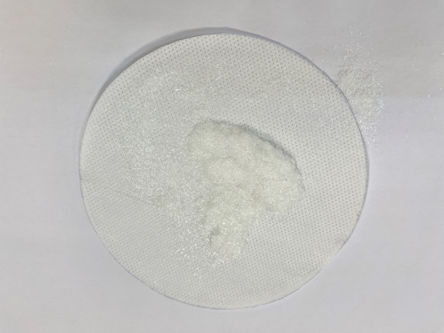

In the first stage of the project, the different methods for conditioning the material have been addressed with the aim of separating the rubber particles present and having a cleaner textile fraction. The next step focused on the depolymerisation reaction of the polyester fraction (PET) using a technology through which chemical monomers suitable for manufacturing new textile fibres have been obtained. The last step of the project focused on the synthesis of polyester from said monomers, obtaining a polyester filament suitable for 3D printing, from which a piece was manufactured as a demonstrator.

The researchers conclude that on a laboratory scale it has been possible to recover polyester fibres from the textile fraction, but now the challenge is to be able to guarantee performance and quality on a pilot scale since the results obtained have not been entirely satisfactory. For this reason, work has already begun on other different forms of recovery while advancing in the cleaning technology of the textile fraction, which has been the limiting factor of this project.