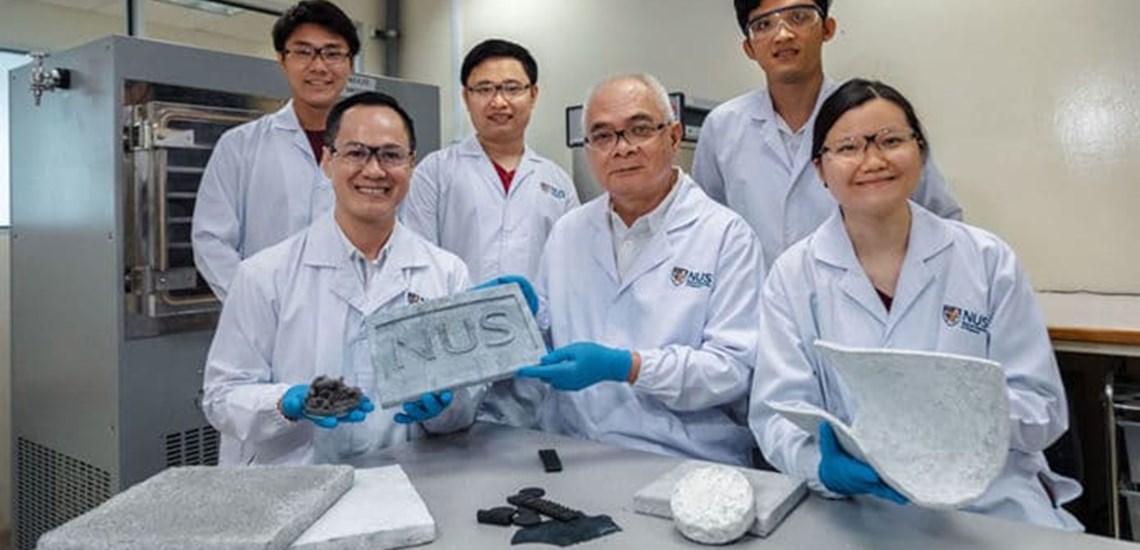

National University of Singapore (NUS) scientists have developed super-light aerogels with new properties that are lightweight, highly absorbent, very durable, and highly efficient at trapping heat and sound. They have developed the aerogels from waste tyres. The aerogels could promote more extensive use of scrap tyres and offer an eco-friendly way to recycle used rubber.

Aerogels from Recycled Tyre Rubber

An aerogel is a synthetic porous ultralight material derived from a gel, in which the liquid component for the gel has been replaced with a gas. The result is a solid with extremely low density and extremely low thermal conductivity.

Associate Professor Duong Hai-Minh, who leads the research team from the Department of Mechanical Engineering at NUS Engineering said; “Although 40 per cent of waste rubber tyres are recycled, the rate of recycling worldwide remains low because processing used rubber is costly and energy-intensive, coupled with a lack of monetary incentive.

“Our team has decided to focus on creating rubber aerogels from used rubber tyres because they are a cheap and abundant source of raw materials. By converting waste rubber tyres into high-value aerogels, we could enhance the monetary incentive for recycling rubber and, in turn, cut down rubber waste.”

Scientists started with recycling car tyre fibres that are then soaked in water and a minimal amount of chemical cross-linkers. Next, the mixture of rubber fibres and eco-friendly solvents is dispersed uniformly using an agitator for 20 minutes. The smooth suspension gel is then freeze-dried at minus 50 degrees Celsius for up to 12 hours to produce rubber aerogels.

Assoc Prof Duong said; “The fabrication process is simple, cost-effective and eco-friendly. The entire production process takes between 12 to 13 hours to complete, and it only cost less than S$10 to produce a sheet of rubber aerogel that is one sqm in size and 1cm thick. The process can also be easily scaled up for mass production. This makes rubber aerogels a commercially attractive product.”