Freetown Waste Management revolutionises Nigerian flooring sector

Flooring from Tyres in Nigeria

Freetown Waste Management Recycle, a Nigeria-based start-up, is revolutionising the tyre recycling sector in the West African country by transforming used car tyres into high-demand, reusable, eco-friendly rubber flooring products such as paving bricks, rubber mats, rubber tiles, speed bumps and rubber rolls, and is feeding them into hotel chains, gyms, homes, restaurants, schools, event centers, homes of the elderly and more, using sustainable methods and materials in its business processes.

Founded by Ifedolapo Runsewe, an entrepreneur in 2018 in Ibadan, the capital city of Oyo state, located in the southwestern corner of Nigeria, the company commenced operations in 2020 with just four employees. The eco-friendly initiative started from a grassroots level, steering the future of Nigeria’s used car tyres and carpeting industry to align with the growing global shift towards waste management and sustainable development.

Today, Freetown Waste employs over 100 people full-time, recycling over 150,000 waste tyres annually. The company also works indirectly with over 150 people who work as tyre collection agents, sourcing old tyres from the dumping grounds and earning as little as ¢17-¢24 per tyre.

Theophlius Okoyomon, chief operating officer, Freetown Waste Management Recycle says the company was incorporated in Nigeria in 2018 specifically as a recycling and manufacturing company. According to him, what spurred Ifedolapo, the founder, into this venture was the unemployment rate in Nigeria, which was as high as 22.6% in 2018, having increased from 10.6% in 2012.

In March last year, the National Bureau of Statistics (NBS) reported that Nigeria’s unemployment rate climbed to 33.3 percent in the fourth quarter (Q4) 2020 from 27.1 recorded in the second quarter (Q2) 2020. The report claimed that a total of 23.18 million persons in Nigeria either did nothing or worked for less than 20 hours a week, making them unemployed during the fourth quarter (Q4) 2020.

While unemployment stands over the roof, environmental pollution due to the practice of landfilling and open burning of discarded tyres which sends dangerous pollutants into the ozone layers negatively impacts the lives of many Nigerians.

Theophlius said “these were the things that spurred us into setting up this company. We looked at environmental issues like the discharge of dangerous pollutants and emission of carbon into the environment and decided to set up this facility to recycle scrap tyres because of the obvious dangers they pose to the environment.

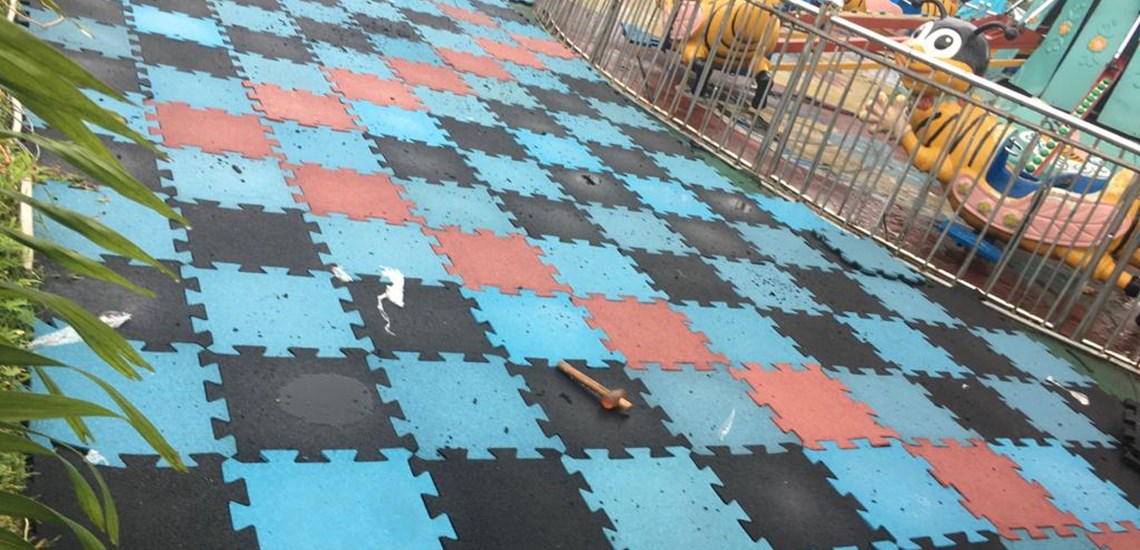

“So, instead of burning tyres, emitting carbon into the atmosphere, we manage and transform them into eco-friendly rubber flooring products such as paving bricks and floor tiles for homes, offices, children’s playground and many more.”

Although Nigeria’s waste rubber flooring industry is still at its infancy, it is gradually gaining recognition among the population, especially with the use of rubber tiles, interlockings, rubber rolls and artificial turf, which has become a popular trend among the tech offices, homes, recreational parks, children’s playground, and public buildings in cities across the country.

The Nigeria rubber flooring market is expected to grow as demand for housing continues to rise to cater for the country’s teeming population.

While transportation in Nigeria is hugely dependent on the road, Okoyomon says it is a vicious cycle that works to the advantage of Freetown Waste, “the more houses are springing up, the more the population is rising, and the more people are buying cars. In as much as cars have four tyres, our primary raw material, which is tyres, will continually be made available for recycling.”

Okoyomon likens tyre recycling to a new type of black gold which creates a pool of wealth if properly harnessed.

“Recycling today is a craft type operation where the real waste-to-wealth is embedded, we produce underlays used under Astro turf (green grass) for football pitches. Our product has various applications that make them stand out for different purposes,” he added.

“We are the very first company in Nigeria doing what we are doing right now. I think people are gradually beginning to see that there is so much potential in the reuse of waste tyres, the acceptability is on the increase, people are beginning to see that our innovation is somewhat different from the regular products available out there,” he told Tyre & Rubber Recycling.

So far, more than 100,000 tyres have been recycled into the company’s end products, But the goal is to recycle 15 million tyres per annum into reusable useful products for residential, commercial, and industrial use with a clear vision of being the leading recycled rubber manufacturing company in Nigeria.

“We have a production capacity of about three tons which is more than 1,000 tons per annum. And that is for our crushing line alone. The same goes for our tile making line that makes our tiles, which produces about 400m2 of tiles produced daily. We also have a mat making line which manufactures 3,300 m2 of rubber roll and rubber mats daily,” said Okoyomon.

In addition, the tyre recycling plant was recently awarded the certificate in Environmental Impact Assessment (EIA) by the Oyo State Ministry of Environment and Water Resources, and the company is currently making efforts to get the Federal Ministry of Environment to approve its EIA at the national level.

On top of that, Freetown Waste Recycling Management has a manufacturing certificate from the Federal Ministry of Trade and Investment, is a member of Manufactures Association of Nigeria, and is currently working on getting approval from the Standard Organisation of Nigeria, an organization that is vested with the responsibility for standardising and regulating the quality of all products in Nigeria.

The tyre recycling company serves a wide range of customers who are scattered across Nigeria and neighbouring African countries including Rwanda and Equatorial Guinea and has plans to expand to other countries like Ghana, Kenya, Senegal, Gambia, and South Africa. It is also making plans to setup an operating facility in the United Kingdom in the future.

However, this is not part of the company’s immediate plans. Okoyomon explains that “we have already put our hands to the plough to kick-start operations, but we want to ensure that we have done all that needs to be done here in Nigeria first before we expand. “Eventually, we are planning to set up recycling lines in all other states in Nigeria, so we should be crushing tyres in Kano, Kaduna, Lagos, and Abuja in future, so, we are having all these plans in-country before spreading out to other African countries and further afield. Currently, we produce at our plant in Ibadan and distribute to our customers at various locations.”