New website from IRR Manufacturing lays out the processes and costs of operating their pyrolysis plant.

Manufacturing Takes the Mystery Out of Pyrolysis

Carlton Forest Group’s IRR Manufacturing, the South African manufactured and UK led pyrolysis process supplier has taken a step ahead of the market by launching an updated website that puts the company’s offer to the pyrolysis sector up front and in the open.

In a world full of vagueness about the process package, and obfuscation of the realities of polymer pyrolysis IRR Manufacturing have taken the unusual step of being up front about the typical processes and the costs associated with establishing an IRR Pyrolysis plant. This is being done through a series of four packages, each presented fully on the updated website.

Whilst the Carlton Forest Group is keen to see pyrolysis as a route to reducing energy costs, its focus is on disseminating the technology to deal with waste in a beneficial way for the operators. The model is built on localised plants providing heat and energy to the vicinity of the plant.

IRR Commercial Director, Alex Matthias explained in an interview with Tyre and Rubber Recycling the idea behind the packages.

“One of the big problems with pyrolysis is that everyone wants a bespoke process and nothing really happens in some cases. So, I came into the business and looked at the market and decided that we needed to declutter what was available. We have created four generic products, which deliver four different outputs for four different process packages for different reasons for different users. It makes the offer understandable”

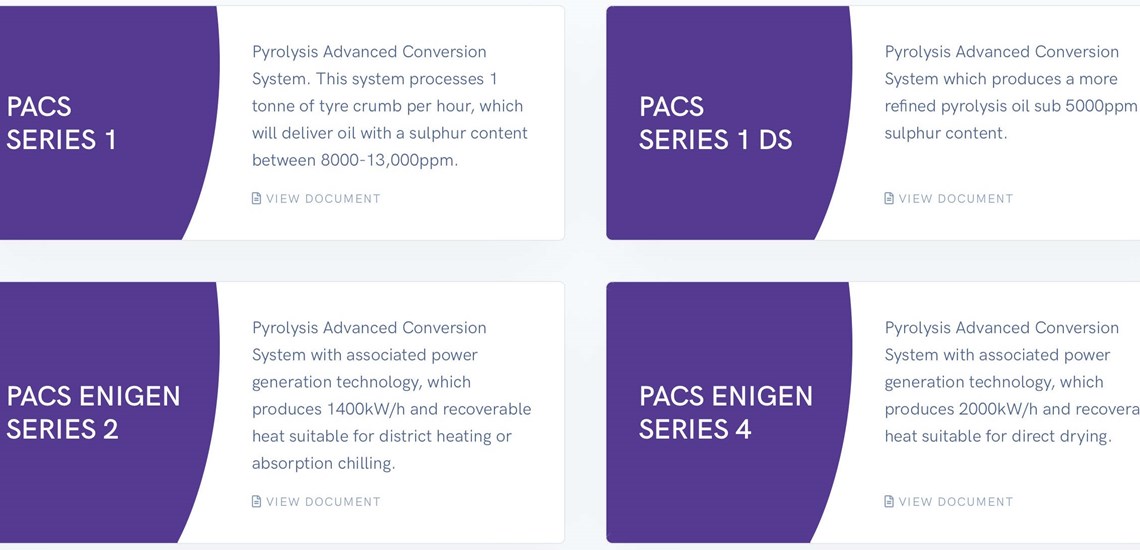

The four packages offered are as follows:-

- PACS Series 1 – Pyrolysis Advanced Conversion System capable of processing 1 ton of tyre crumb per hour to create tyre derived oil at 8000ppm Sulphur content.

- PACS Series 1 DS – as above but producing a cleaner fuel at 5000ppm Sulphur content

- PACS Enigen Series 2 – Pyrolysis Advanced Conversion System with associated power generation technology that can generate 1400Kw/h of electricity and provide renewable heat suitable for district heating, or absorption chilling.

- PACS Enigen Series 4 – Pyrolysis Advanced Conversion System producing 2000Kw/h of electricity plus renewable heat suitable for direct drying.

The website takes visitors on a detailed tour of each of the packages with concise information that answers many questions. Each package is shown with a cost, plus layout details and a catalogue of requirements that allows the client to readily develop site specific costs for establish a plant.

The Carlton Forest Group approach to pyrolysis differs from the norm, in that many processors are searching for a pot of gold that is difficult to access – the investor with pockets deep enough to fund the commercialisation trials and tribulations of establishing a business operation involving a process that is wrapped in smoke and mirrors.

IRR has developed a package that is workable “out of the box”. It is a tried and tested continuous pyrolysis process, it comes with the facts, figures and guarantees. It is operating to European standards and can be up and running in any suitable location within months of gaining a suitable permission from the local authority.