The Mitsubishi Chemical Group has launched studies to perform chemical recycling of end-of-life tyres by utilising the coke ovens at its Kagawa Plant

The MCG Group aims to begin marketing sustainable carbon black made from ELTs by March 2026.

Along with the accelerating trend in the tyre industry toward using sustainable raw materials, there is a growing need to use recycled carbon black, one of the main raw materials and a rubber reinforcing agent used in tyres.

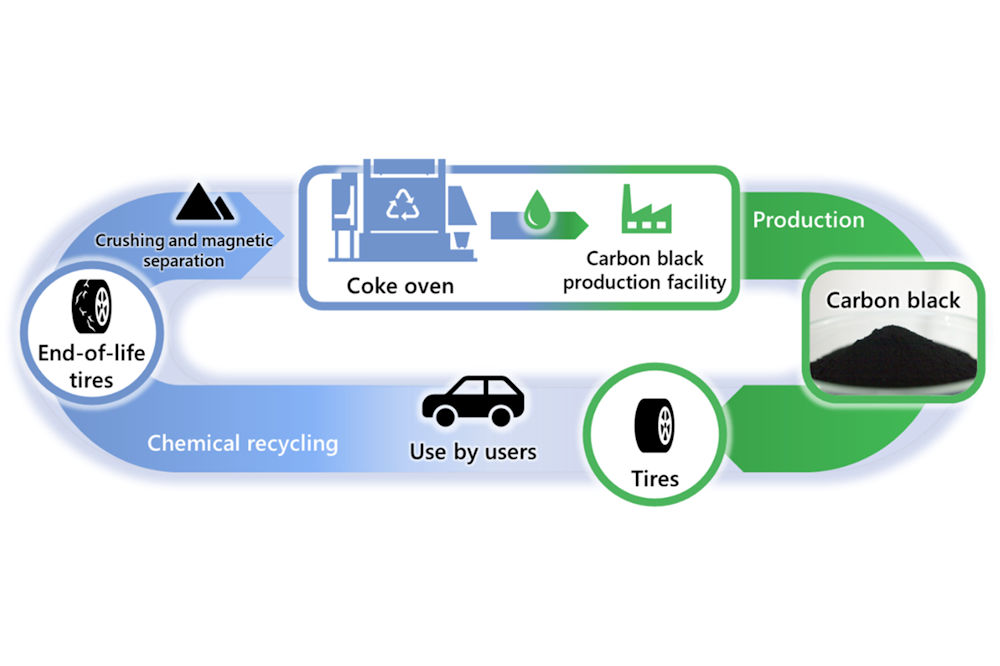

By leveraging the MCG Group’s supply chain, it is able to feed crushed ELTs as raw material into its coke ovens and produce carbon black again from the tar.

According to the MCG Group’s research, this is the first attempt in the world to produce sustainable carbon black from ELTs using coke ovens. (In fact, there were trials at Coalite’s plant in Derbyshire, UK to convert coke ovens to pyrolyse tyres, but the Company collapsed in 2004, before the trials were completed). The sustainable carbon black produced has the same performance as conventional carbon black and can therefore be used again in new tyres and hence contributes to a closed loop recycling of tyres.

In preparation for commercialisation, in July 2024, MCG started demonstration experiments where ELTs are fed into coke ovens. The aim is to sell sustainable carbon black at an annual rate of several thousand tons in FY2025, and at an annual rate of tens of thousands of tons in FY2030.

By establishing chemical recycling technology for ELTs, the MCG Group seeks to contribute to realizing a circular economy in the automobile and tire industries.