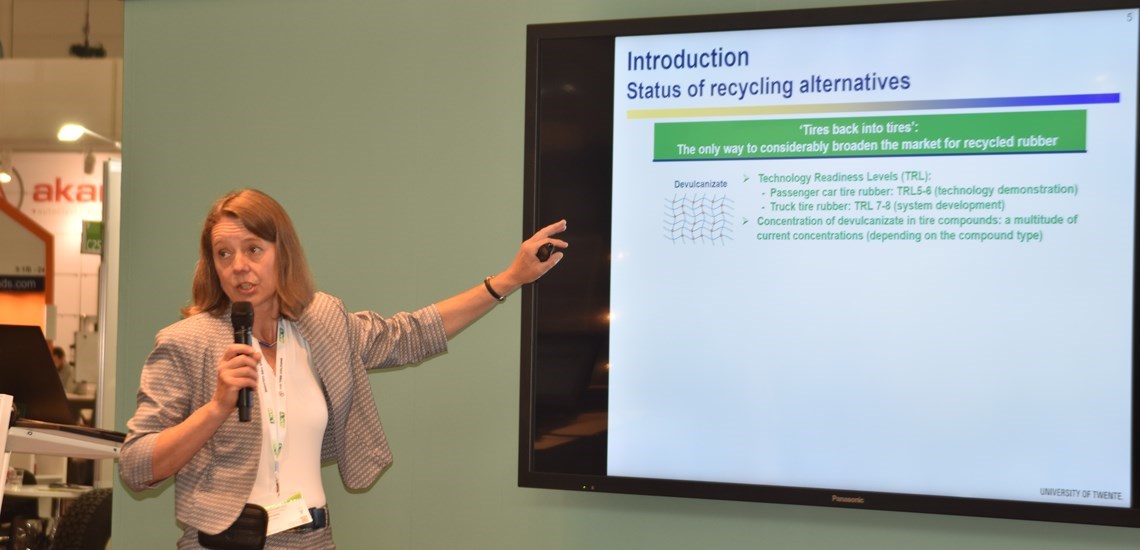

Dr. Wilma Dierkes , of the University of Twente has spoken at conferences and seminars about fast pyrolysis of tyres. The theory is that a “flash” process can be used to bring abut the reduction of tyres, or other wastes, in a short time with a lower energy cost than conventional pyrolysis.

Continental and the University of Twente Collaborate to Improve Pyrolysis Process

Now, Continental is working with the University of Twente to develop the process, which could create the opportunity for rCB to be reused in new tyres

The University of Twente and Continental are eager to push the boundaries of end-of-life tyre recycling to achieve a more sustainable solution. The novel approach may also reduce a shortage of carbon black experienced by U.S. tyre producers.

The research initiative is co-funded by the Dutch Materials Innovations Institute. Project leader Professor Gerrit Brem, from the university’s thermal engineering department, says the ‘breakthrough’ is the result of combining the best from the worlds of energy technology and materials engineering.

According to Dr Wilma Dierkes of the Elastomer Technology & Engineering department: ‘A successful development means that the innovative pyrolysis process contributes to a high percentage of recycled tyres and other rubber materials in cradle-to-cradle cycles for sustainable car tyres.’

She points out that the fast pyrolysis technique is also capable of converting other waste flows into high-quality materials. Examples include: fuels and minerals from paper sludge; carbon fibres from transport and industrial composite waste; or glass fibres from disassembled boats or wind turbines.