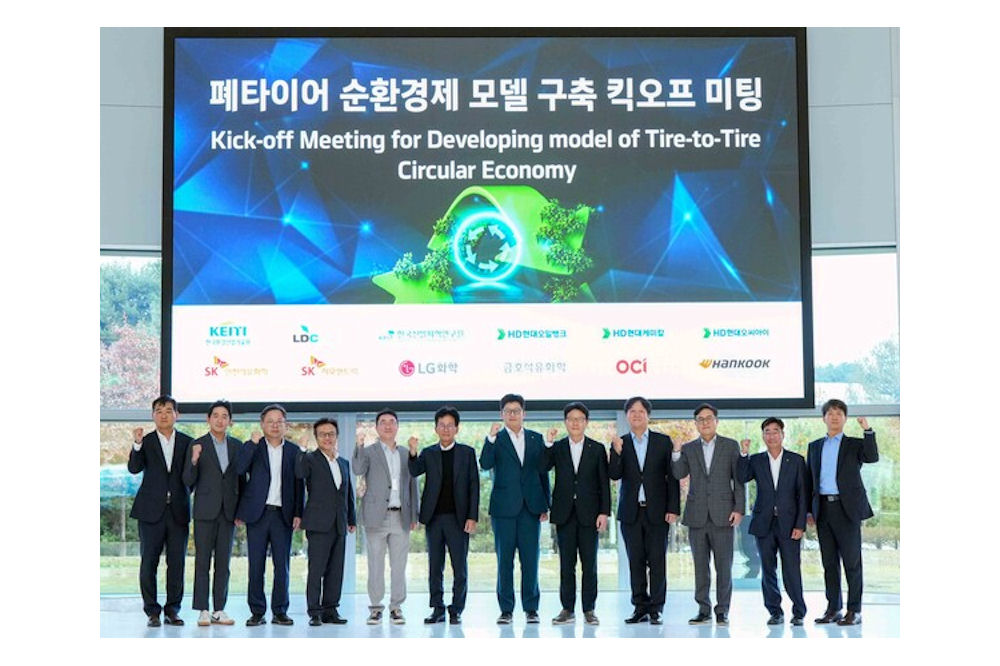

Hankook Tire & Technology (Hankook Tire) hosted the official kick-off meeting for the “Tire-to-Tire Circular Economy Model” consortium on November 1 in Daejeon, South Korea

Held at the Hankook Technodome, the event marked the start of the consortium’s efforts to create the business model for the circular economy of end-of-life tyres in Korea.

Initiated by Hankook Tire, the “Tire-to-Tire Circular Economy Model” project aims to promote a circular economy of end-of-life tyres in the industry sector by designing innovative upcycling processes for turning end-of-life tyres into new tyres. This project signifies industry commitment to meeting global demands for carbon neutrality and using more sustainable materials in the manufacturing process. Twelve companies and institutes including Hankook Tire, Korea Environmental Industry & Technology Institute, LD Carbon, Korea Institute of Footwear & Leather Technology, HD Hyundai Oilbank, HD Hyundai Chemical, HD Hyundai OCI, SK Incheon Petrochem, SK Geo Centric, LG Chem, Kumho Petrochemical and OCI will collaborate on the project with the goal of improving the industry’s shift toward sustainability.

The group aims to bring together the expertise of its members to identify and produce sustainable materials such as recovered carbon black, which can be used in new tyre manufacturing.

The consortium aims to build a system to steer access to high-quality, sustainable raw materials. Additionally, the group intends to seek R&D support from government ministries and affiliated organisations to accelerate the development of standardised technologies and processes.

“It is an honour to host such a meaningful consortium. Our efforts to establishing this model for circular economy of end-of-life tyres, will play a vital role in strengthening a more sustainable value chain for the industry, helping replace conventional petrochemical-based raw materials with high-quality secondary raw material,” said Bonhee Ku, Chief Technology Officer of Hankook Tire & Technology.

This move in Korea follows the example set by Blackcycle in Europe and could see some key changes in how manufacturers appraise and adopt new recycling technologies.

Source:Business Korea