Gecko bicycle tyres can be recycled and can contain recycled rubber

Recyclable Bicycle Tyres Sold by Gecko

It is always difficult to take new technology into the marketplace, always harder when there are preconceived ideas based on historical practices. The first bicycle and car tyres were solid rubber, a huge advance on steel rimmed wooden wheels. However, after many trials, along came Dunlop with the pneumatic tyre, and apart from a few specialist applications, the solid tyre was consigned to history.

That was until Richard Adams developed the patented Gecko solid tyre, which he claims offers a good ride, a puncture proof capability, a longer life and, crucially, ease of recycling and the inclusion of the recyclates in new Gecko tyres.

The bicycle tyre market is largely catered for from the Far East and India, the tyres are cheap, and largely have a traditional textile belting and a high tensile steel wire beading that make them difficult to economically recycle.

There is a growing market in some areas of cycling, mountain biking, in particular, for foam inserts that provide better protection than sealants. However, the Gecko, according to Adams, is relatively easy to fit, and once fitted can be forgotten about. There are no punctures to worry about.

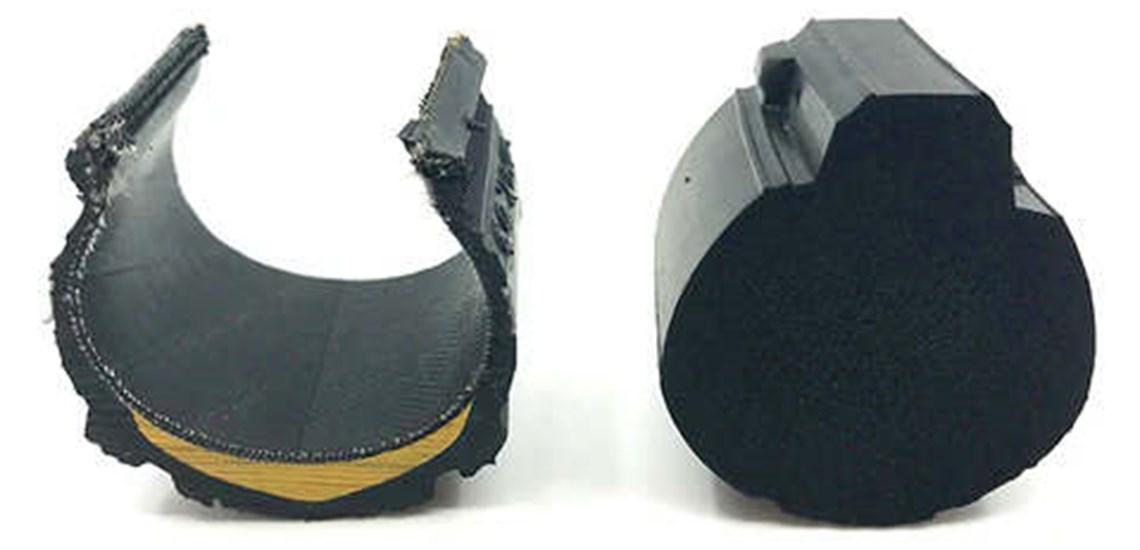

The tyre is a type of closed cell construction internally and comes after many years of research and development. Adams’ background is in rubber technology, as was his father’s. and the Gecko tyre has been a long-term project.

The lack of textiles and wire in the Gecko makes the tyre readily recyclable, and after grinding, the rubber can be reintroduced to new Gecko tyres at a rate of around 10 per cent.

Adams has bigger markets and alternative versions of the Gecko, but the initial entry into the market is planned to be through bicycle tyres. Gecko is looking for distributors and sales outlets, and part of the arrangement would be a return collection service in due course, so that the process becomes cyclic (no pun intended).

Like so many new projects funding is critical to make this happen, and Adams has his work cut out for him in finding ways to market and collect this new product, plus he must overcome a hundred years of pneumatic bicycle tyre successes.

There are some drawbacks, the rolling resistance is a little higher than a conventional tyre, but in city bike and bike rental programmes, the rolling resistance is less of an issue when compared to puncture repairs and maintaining tyre pressures. Adams commented; “The increased use in electric bikes somewhat compensates for the higher rolling resistance. However, we are looking at city bike schemes and the like as initial markets.”

Operating with city bike schemes addresses the distribution and collection issue as well as opening a sizeable market.

Amongst the wider applications are any markets where a puncture proof tyre is required, and even as an alternative to existing solid tyres on forklift trucks.