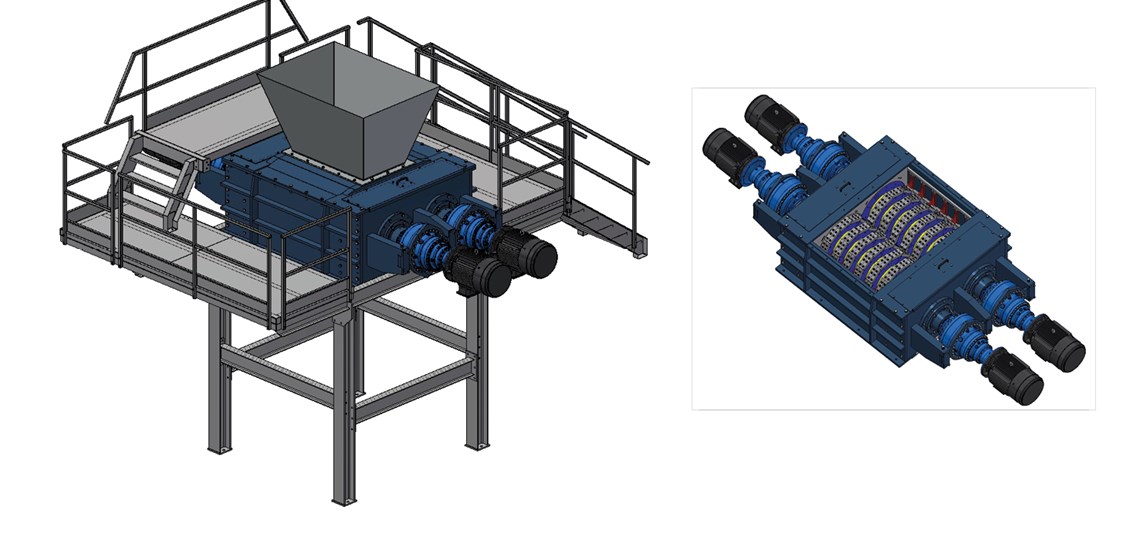

Danish manufacturer of recycling equipment, Eldan Recycling, has launched a new Twin Shaft Clean-Cut Shredder (TSCC) for the production of clean-cut tyre chips from car or truck tyres.

New Shredder from Eldan

The simple construction enables easy knife change, by lifting up the entire rotor. Knives can also be reground. Two rotors, each equipped with two electrical motors and high torque gearboxes. Wear-resistant knives for efficient pre‐shredding. Two frequency converters ensure a very flexible operation, i.e. individual setting of RPM, overload protection, auto reverse at overload and high torque from zero RPM. Up to 50% power saving. Stand and inlet hopper customized for individual setup.

“The Eldan Twin Shaft Clean-Cut Shredder is the optimal machine for recyclers who want to go from complete tyre into 50 mm or 100 mm clean-cut chips in one go,” says Jan Kjær, Manager R&D at Eldan Recycling. “The unique solutions designed for the Eldan Twin Shaft Clean-Cut Shredder is patented.”

The Eldan Twin Shaft Clean-Cut Shredder can produce clean-cut 50 mm chips from car or truck tyres at up to 6000 kg/hour or clean-cut 100 mm chips at up to 9000 kg/hour.