Continental uses synthetic rubber made from recycled oil, with a goal of increasing the use of sustainable materials in tyre production

Continental revealed that the use of renewable and recycled materials in its tyre production averaged 26% in 2024, and the company hopes to see an increase of 2 to 3 percentage points by the end of this year. By 2030, this figure is expected to rise to at least 40%. Among other materials, Continental focuses on rubber and resins from various more sustainable sources.

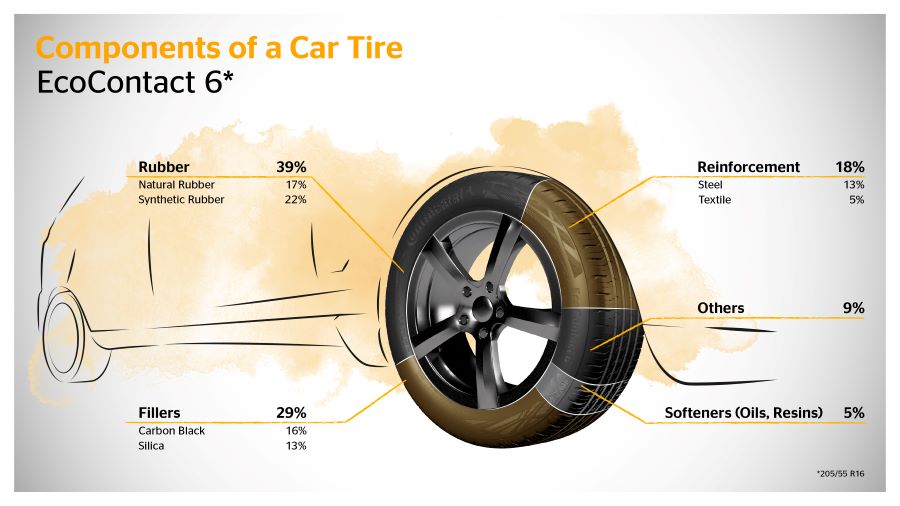

Synthetic rubber from renewable and recycled materials and responsibly sourced natural rubber are crucial in more sustainable tyre production. This is due to the high content of this key raw material in every tyre produced, with modern high-performance tyres consisting of up to 40% rubber by weight. The actual type of rubber used in a tyre depends heavily on the component in question and the function it performs. Continental car tyres are manufactured using up to 100 different raw materials, which in turn are used to produce up to 20 different customised rubber compounds per article, among other things. These also contain recycled variants of additives and supplementary raw materials, as well as circular resins that make the resulting rubber more pliable and improve overall tyre performance.

“We’re closing the loop: Continental is ramping up its commitment to a circular economy and mapping out its path for the future,” says Jorge Almeida, head of Sustainability at Continental. “Innovative solutions enable us to use more sustainable raw materials, such as synthetic rubber made from used cooking oil or resins based on certified renewable feedstocks originally derived from vegetable oil.”

Continental mainly uses two categories of rubber, each offering specific technological benefits for specific tyre components: natural rubber and synthetically produced rubber.

Natural rubber – which is typically used in tyre production – is used, for example, in the treads of car and truck tyres, where the rubber needs to be extremely hard-wearing. Its special properties include its impact resistance and durability, thanks to the strain-induced crystallisation inherent in naturally grown rubber. This unique feature of natural rubber cannot yet be reproduced artificially.

Meanwhile, synthetic rubber is incorporated into the car tyre treads in addition to natural rubber because of its superior braking performance and rolling resistance. Continental is increasingly using synthetic rubber derived from, for example, pyrolysis oil made from end-of-life tyres or used cooking oil, sourcing it from suppliers such as Synthos and TotalEnergies Cray Valley, both of which are using a mass balance approach, valorising sustainable sources certified by the ISCC PLUS International Sustainability and Carbon Certification. The production processes and raw materials used to manufacture the synthetic rubber supplied comply with this system.

Continental uses circular resins produced by suppliers like TotalEnergies Cray Valley that are ISCC PLUS-certified, sustaining along the value chain the development of renewables feedstocks originally coming from vegetable oil or used cooking oil. Continental also uses the ISCC PLUS-certified rubber additive TMQ from LANXESS. According to life cycle assessments, this additive, produced from raw materials such as biocircular acetone, has a carbon footprint that is more than 30% lower than its conventionally manufactured counterpart. Biocircular acetone is made from waste of biological origin, like recycled cooking oil.

The use of such materials is possible thanks to the mass balance approach, which involves mixing fossil, renewable and recycled materials during the manufacturing process and tracking them as they move along the value chain. This allows the company to attribute the input of renewable and recycled raw materials to the output of the final product and thus precisely document – and successively increase – the use of ISCC PLUS certified materials.

“The mass balance approach enables us to efficiently manage the complexity of the raw materials portfolio and track how these raw materials are used at multiple production sites in a wide range of markets,” explains Matthias Haufe, head of Material Development and Industrialisation at Continental. “In this way, we can steadily increase the share of renewable and recycled materials in our tyre production – and transparently document the progress we make.”