Continental is meeting one of the holy grails for tyre recyclers to get tyre-derived materials back into tyres

There is anecdotal evidence of tyre manufacturers utilising tyre derived materials but the question of what and how much is used often goes unanswered.

Now, Continental has talked about its solid tyres using recovered carbon black.

At the company’s plant in Korbach, Hessen, recovered industrial carbon black (rCB) is being added to newly produced Super Elastic solid tyres, thus reducing the use of fossil materials and cutting CO2 emissions.

Solid tyres such as Continental’s SC20+ already contain around 60 per cent renewable and recycled materials thanks to their high natural rubber content. By 2050 at the latest, Continental aims to use 100 per cent sustainable materials in its tyre products.

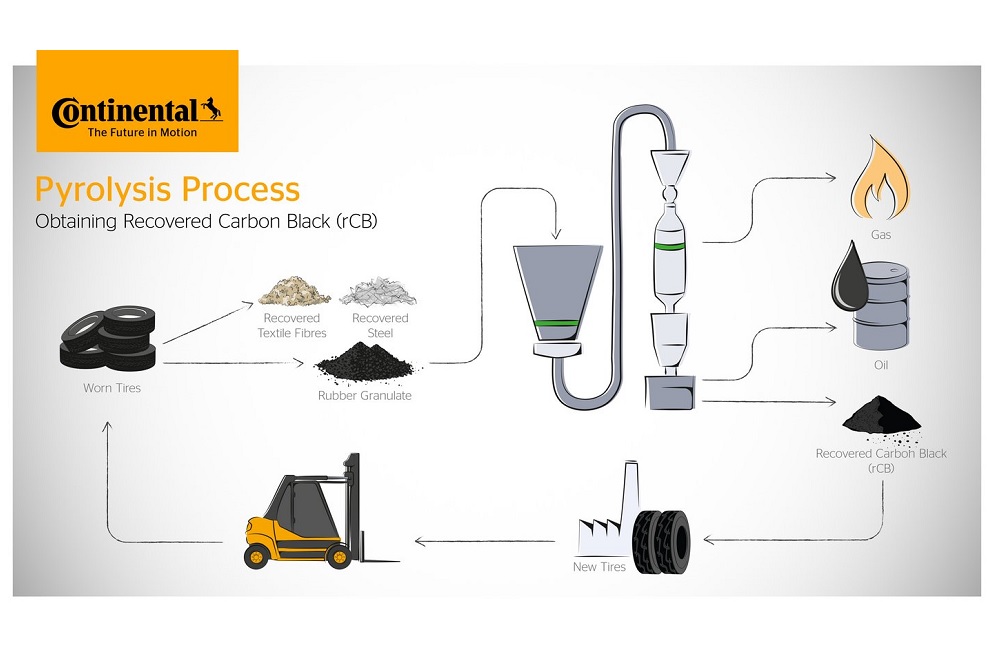

The recovered carbon black is supplied by Pyrum Innovations, one of Continental’s partner companies. Pyrum breaks down end-of-life tyres using a proprietary pyrolysis process. This allows valuable raw materials contained in end-of-life tyres to be extracted and recycled. Solid tyres have a high load capacity and are extremely stable, puncture-proof, maintenance-free and highly economical. They are mainly used in material handling by forklift trucks, airport vehicles, heavy transport vehicles, sideloaders, platform trucks and other industrial vehicles.

“Sustainability is becoming increasingly important in the specialty tire segment. Our Super Elastic solid tyres combine low rolling resistance, long service life and a comparatively high proportion of sustainable materials,” says Matthias-Stephan Müller, product manager for material handling tyres in Continental’s Specialty Tires business area.

RCB from an efficient pyrolysis process

Industrial carbon black is an important resource used as a filler in tyre production and in the manufacture of other industrial rubber products. The targeted use of carbon black in rubber compounds increases the stability, strength and durability of tyres.

“In Pyrum, we have found a partner that has developed a particularly efficient pyrolysis process. Together, we want to further develop the process for the pyrolysis of end-of-life tires,” explains Matthias Haufe, Head of Material Development and Industrialisation at Continental Tires. In the future, the recovered carbon black will also be used in other Continental compounds. Jointly with Pyrum, the tyre manufacturer is currently working on further optimising and expanding the recycling of end-of-life tyres using pyrolysis.

The use of recovered carbon black from end-of-life tyres is an important step toward more circular business practices in Continental’s tyre production. The company is working tirelessly to advance innovative technologies and sustainable products and services throughout its entire value chain, from sourcing sustainable materials to recycling end-of-life tyres. By 2050 at the latest, Continental aims to achieve 100 per cent carbon-neutrality along its entire value chain.