The correct disposal of end-of-life tyres (ELT) or used tyres is an important and complex issue.

Forrec produces dedicated machinery for waste treatment and tyre recycling. All its granulators, single shaft shredders, and double shaft shredders are designed for volume reduction and to process a wide range of materials: from refrigerators, electrical cables, wood, lightweight plastics, and tyres too.

Specific machineries for tyre treatment: discover the MR series

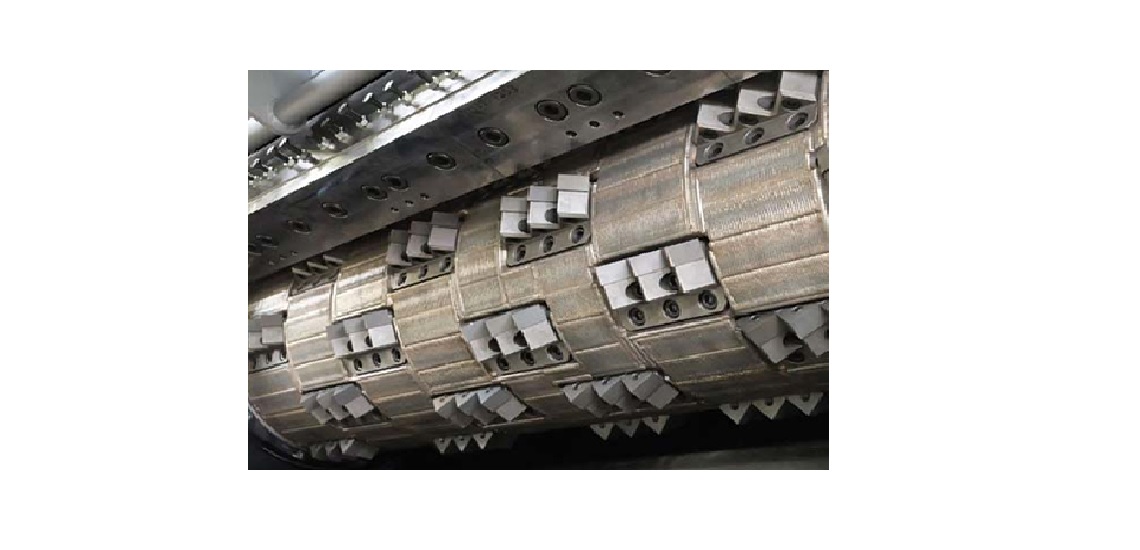

The MR series single shaft shredders are especially designed for application in tyre processing.

In these kinds of applications the mechanical parts are subject to particular stressing, and for this reason the machines have been projected with an oil bath transmission with gearbox without ram to reduce overloads and vibrations. Furthermore, these series include:

- Single shaft with parallel axis engine reducer;

- Configurable automatic gear reversal;

- Bearings outside of the cutting chamber;

- Automatic greasing managed by PLC;

- Epicyclic reducer MR1500 / Absence of reducers MR2000;

- Configurable blades for thickness and number of teeth

Types of Waste Reuction

FORREC’s tyre recycling plants are designed in order to obtain three different types of waste reduction:

- Reduction in size (shredded tyre crumbs): ideal for reducing volumes, facilitating warehousing and energy production, waste becomes an alternative source of fuel;

- Grinding up to 20 mm (chips) separating iron and textile fibers: in this case, the material can be used for thermal treatment or as a substrate in civil and industrial works;

- Secondary raw materials (crumb rubber 0-4 mm): 99% pure material, ideal for application in anti-shock flooring, compounds and mixtures for asphalt, urban furnishings, insulation and sound absorbing panels.

All machines can be customised according to the customer’s needs, available space, and specific material properties. If you want to discover more, visit FORREC’s website: https://www.forrec.eu