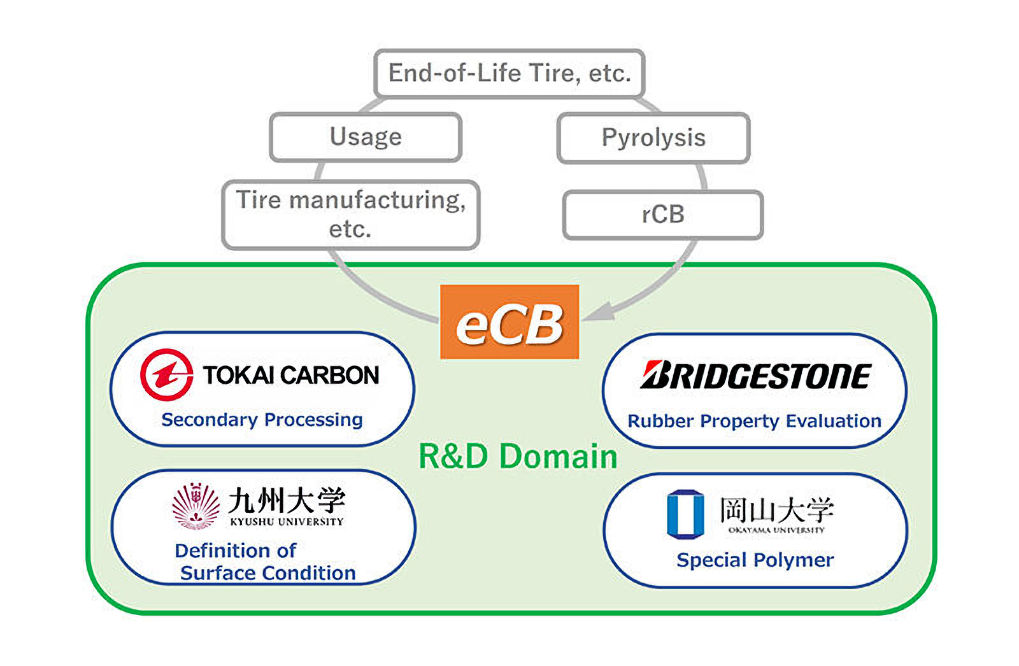

Tokai Carbon Co., Ltd, Bridgestone Corporation, Kyushu University, and Okayama University have launched a technology development project to perform secondary processing on rCB extracted from polymer products such as end-of-life tyres

The project aims to convert these materials into eco Carbon Black (eCB™) with rubber reinforcement properties equivalent to those of virgin carbon black (vCB) that is derived from petroleum and coal. Through these efforts, the joint project members are focused on contributing to the realisation of a circular economy and carbon neutrality through the development of advanced recycling technologies.

This project is a part of demonstrative initiative titled “Technology Development for Carbon Recycling from Polymer Products Including End-of-Life Tires“. The project was selected by the New Energy and Industrial Technology Development Organization (NEDO) on December 23, 2024 under the “Green Innovation Fund Project / Technology Development for Manufacturing Plastic Raw Materials Using CO₂, etc.”

Efforts are already underway to pyrolyse polymer products including rubber from end-of-life tyres to recover and reuse rCB. However, practical application of rCB in new tyres still faces challenges. Among them, rCB has lower rubber reinforcement performance compared to vCB, primarily due to the presence of numerous impurities. Additionally, although many end-of-life tyres are still effectively utilised as fuel through thermal recovery, this process leads to CO2 emissions. With the anticipated growth in automotive and transportation demand, tyre demand is expected to rise correspondingly in the future. These efforts are focused on enhancing resource circulation by further enabling the recycling of vCB, a key raw material for tyres.

In this project, Tokai Carbon will leverage the technologies and expertise it has developed through carbon black manufacturing, combining them with the knowledge and technologies of Bridgestone, Kyushu University, and Okayama University. Together, the joint project members aim to develop technology to remove impurities from rCB and produce eCB with superior rubber reinforcing properties. The project’s objective is to establish a demonstration plant capable of producing 5,000 tons/year of eCB by fiscal year 2032. Additionally, the project will focus on developing special polymer/carbon composites that enable the reuse of carbon black without the need for pyrolysis of end-of-life tires. Through these initiatives, the joint project members want to realise advanced recycling of limited resources and help reduce the CO2 emissions associated with the production of carbon black and the recycling of end-of-life tyres.