Bridgestone Corporation has announced that it has commenced the production of tyre derived oil and recovered carbon black through pyrolysis of used tyres using test units installed at Bridgestone Innovation Park in Kodaira City, Tokyo.

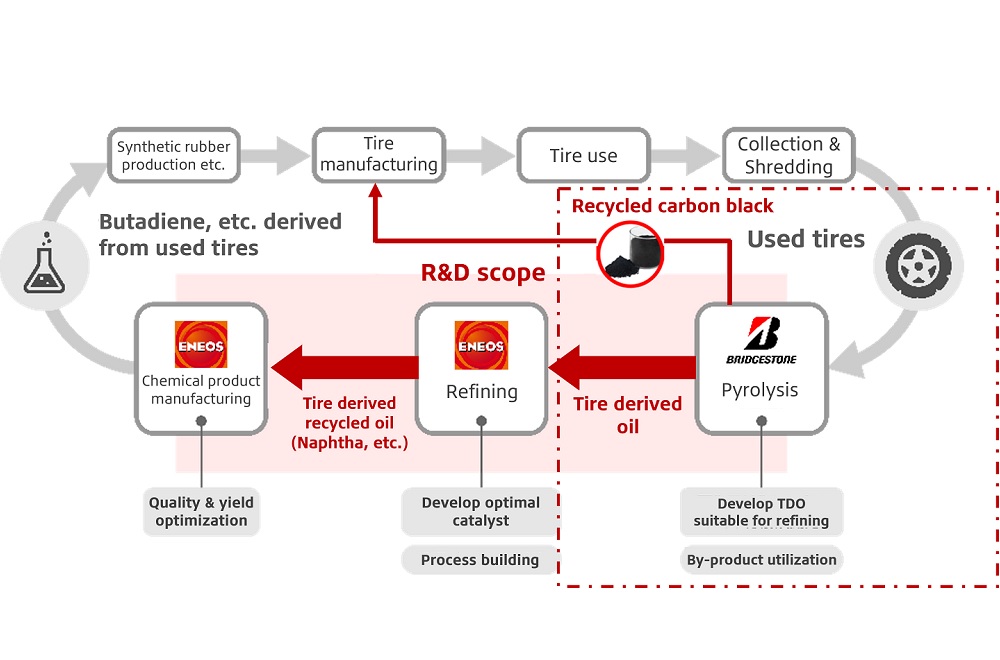

This initiative is aimed at promoting the social implementation of chemical recycling technologies that enable precise pyrolysis of used tyres. The scope of this initiative is indicated by the red boxes in the chemical recycling diagram above.

This project is one of two R&D projects that are part of an initiative for developing chemical product manufacturing technologies utilising used tyres promoted by the New Energy and Industrial Technology Development Organization (NEDO) of Japan and has been adopted as part of NEDO’s Green Innovation Fund.

Bridgestone is currently advancing verification tests on this project as part of a joint project with ENEOS Corporation. This test is aimed at promoting the social implementation of chemical recycling technologies for achieving high-yield production of chemical products, such as butadiene, a raw material used in synthetic rubber.

The companies are moving forward with research and development on the technologies for refining tyre derived oil obtained through precise pyrolysis to create butadiene and other chemical products of ENEOS, which boasts crude oil refining technologies and foundational basic chemical product manufacturing technologies, and the precision pyrolysis technologies of https://www.bridgestone.com/regional/europe_cis/Bridgestone, which possesses advanced rubber and polymer material design technologies. Under this project, large-scale verification tests will be advanced by 2030 with the goal of achieving mass production, and the production of tyre derived oil and recovered carbon black through pyrolysis of used tyres using test units is the first step toward achieving this goal.