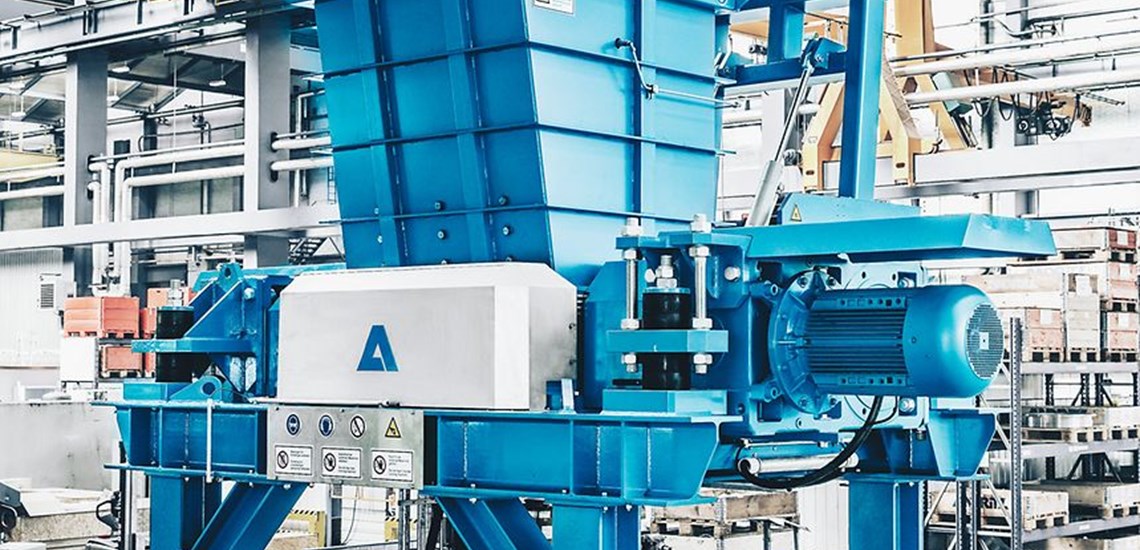

International technology Group ANDRITZ has presented its new ADuro product line of recycling shredders for primary and secondary shredding, fine granulation and for breaking up material composites.

ANDRITZ Launches the “ADuro” product line

ADuro shredders feature the highest durability and are perfectly suited to processing almost all raw materials in the recycling industry. They can be installed easily in existing facilities, thus keeping shutdown times during installation to a minimum.

The latest member of the ADuro product family is a compact secondary shredder with an extra robust design. With a rotor length of 3,200 mm and some unique design features, the machine is a powerful tool for shredding refuse-derived fuels and municipal solid waste as well as commercial or industrial waste. The new shredder will be launched in July this year.

“The ADuro brand name reflects our strong focus on R&D and stands for a continuously enhanced shredder design with IIoT features to achieve the optimum operating point,” says Michael Waupotitsch, Vice President of ANDRITZ Recycling. “The ANDRITZ automation tools can be tailored to individual customer needs and provide powerful capabilities to monitor machine behaviour and improve plant reliability.”

Specifically, suitable for the tyre recycling sector are the UC two-shaft shredders, renamed the ADuro C (with coupled shafts), the UG Granulator is now the ADuro G, and the USM is now the ADuro M.

These machines are established in our clients’ tyre recycling plants, with proven high performance.

The G-RS is a new Series of ANDRITZ Granulators, reinforced for scrap applications, including tyres, with optimised design for maintenance.

ANDRITZ Recycling offers complete recycling lines and plants, including excellent single equipment units such as shredders, which are a critical component in any recycling operation.