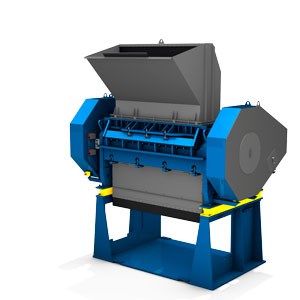

Eldan has introduced a new heavy-duty version of its Multi Purpose Rasper, a heavy duty rasping machine for initial size reduction of materials such as tyres, aluminium scrap, cables, electronic and electrical waste and others.

According to Eldan the latest version of the machine has an increased capacity, being equipped with 264 KW of power and more than double inertia in the flywheel. This gives a more even load of the machine and a higher cutting power. The rpm of the machine has also been increased to 144 rpm, which contributes towards a substantial increase in capacity.

The machine also features a newly designed protection cover, which is capable of protecting the bearing against steel and dirt getting into the bearing.

The machine also features newly designed wear plates on the rotor. The new design keeps the material from building up inside the rotor housing. They also contribute towards extended lifetime of the wear segments and can be easily exchanged without removing the rotor.

The rotor itself also has a new wear-resistant design. It is hard-surfaced welded and can run for 5 times longer than its predecessor before any maintenance is required.

Other key features of Eldan’s Multi-Purpose Rasper are as follows:

- The high inertia from the flywheel gives a more even load of the machine, and therefore a higher cutting power

- Friction clutches protect the machine from material overload

- The machine is belt driven for simple transmission

- Adjustable knife clearance optimize the cutting function

- The knives can be reground multiple times on a “flat-bed” grinder ensuring long life and low operation costs

- The machine is designed for quick and easy change of knives and screens

- The rotor is manufactured and designed for minimum wear

- Screens with different hole sizes available for flexible production

- Exchangeable wear parts assure a virtually indestructible machine

If you would like to contact Eldan, please fill in the contact form below and we will pass on your enquiry to them