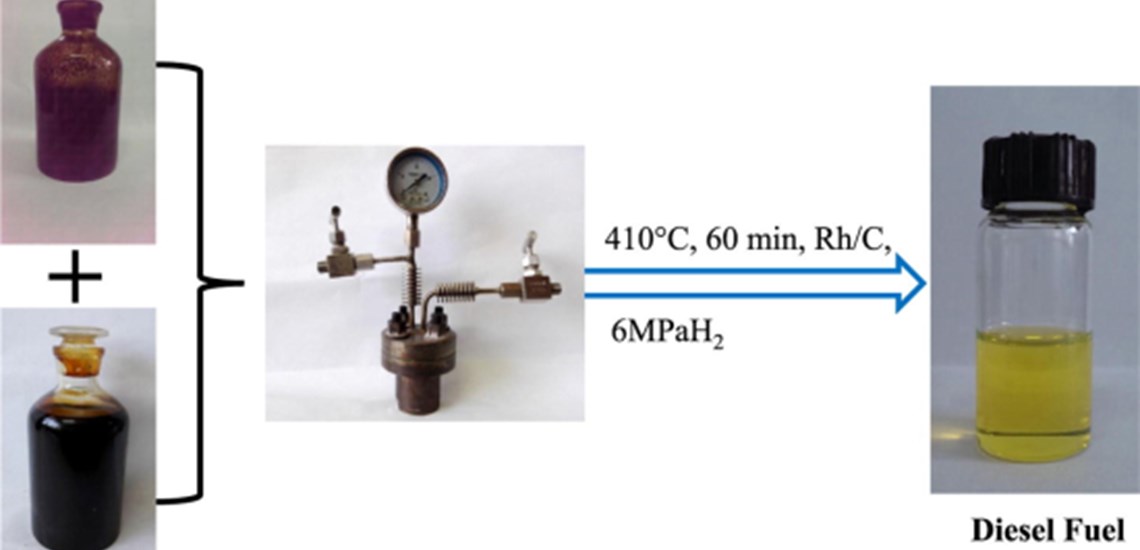

Researchers at Henan Polytechnic University in China have hydrotreated the oil derived from hydrothermal liquefaction of scrap tyres (STO) with waste engine oil (WEO) using five different activated carbon-supported noble metal catalysts—Pd/C, Pt/C, Ru/C, Ir/C, and Rh/C—for the production of liquid fuels.

Chinese Research Blends Engine and Tyre Oil to Create Diesel

In a paper in the journal Fuel, they report that among the catalysts, Rh/C showed the highest performance for sulphur removal from the resulting upgraded oil (UPO). With Rh/C, the effects of other reaction parameters, such as temperature (350–450 °C), catalyst loading (1–20 wt%), reaction time (30–150 min), STO/WEO mass ratio (0:5–5:0), and initial H2 pressure (0.1–9 MPa), on the yield and property characteristics of the UPO were optimised.

The STO/WEO mass ratio and initial H2 pressure were the two main parameters that markedly affected the yield and property characteristics of the UPO. Using WEO as the reaction medium not only made the recovery of the UPO easier but also converted WEO into a major component of the UPO. WEO also suppressed coke formation and thus prolonged the lifetime of the catalyst.

The UPO dominantly consisted of hydrocarbons (saturated and unsaturated) and aromatics whose contents were predominantly affected by the STO/WEO mass ratio and were very close to the mixture proportions of jet fuel and light diesel.

In general, the thermochemical conversion of scrap tyres (ST) is a thermal decomposition process that produces recyclable solid, liquid and gaseous products. The liquid-state product, generally called oil, is one of the most promising feedstocks for use in fuels or chemicals. However, this kind of oil is usually characterised by high viscosity and high contents of N and S atoms. Therefore, additional processing is necessary to further decrease the N and S contents and viscosity of this oil prior to its utilization.

Currently, hydrotreatment is one of the most popular methods for the upgrading of bio-oil. This method simultaneously involves hydrodesulfurisation (HDS), hydrodenitrogenation (HDN), and hydrodeoxygenation (HDO) to eliminate S, N, and O heteroatoms in the forms of H2S, NH3, and H2O, respectively, from bio-oil.

… Recently, considerable and increasing attention has been paid to the management or reuse of waste lubricating oil, particularly engine oil. According to statistics from the Chinese transportation industry, 25–30 million tons of waste engine oil (WEO) are produced every year, which can cause serious environmental contamination if the WEO is improperly disposed of. WEO, which has been suggested to be a promising medium for bio-oil upgrading, can not only enhance the mutual solubility of bio-oil and WEO but also reduce the generation of carbon deposits. In addition, WEO can be converted into the final product oil.

Therefore, in the present study, WEO was used as a medium for scrap tyre oil (STO) upgrading. —Liu et al.

The researchers concluded that co-hydrotreatment of STO and WEO blends is an effective way to obtain liquid fuel that can be used directly for combustion or act as a co-feeder for a petrochemical refinery. They found that the WEO could also be recovered as a major fraction of the UPO and used to adjust the relative proportions of the UPO components by varying the initial STO/WEO mass ratio.

The researchers concluded that co-hydrotreatment of STO and WEO blends is an effective way to obtain liquid fuel that can be used directly for combustion or act as a co-feeder for a petrochemical refinery. They found that the WEO could also be recovered as a major fraction of the UPO and used to adjust the relative proportions of the UPO components by varying the initial STO/WEO mass ratio.

Source: Green Car